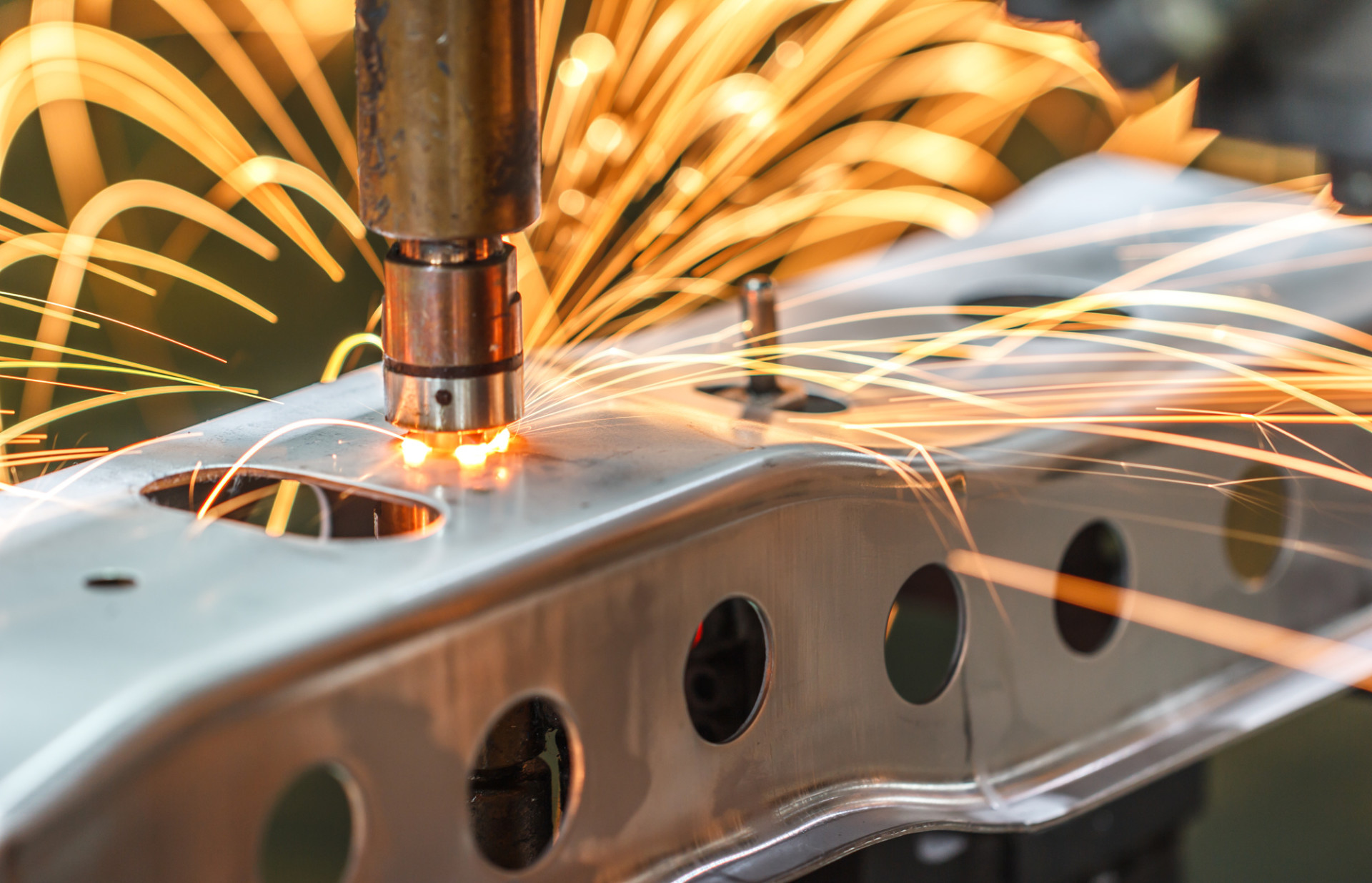

Laser gas welding distribution systems- also called laser beam welding (LBW), are machines utilized in welding to fuse metal bits using a laser beam. The beam from the laser permits a targeted supply of warmth, which then offers high, constant rates of uniform and welding welds.

Comparable to electron beam welding (EBW) systems, higher durability, and targeted electricity laser welding generates heat affected regions which have highly concentrated heat and cooling prices. The smaller dimensions are especially beneficial in welding. The quantity of electricity is in direct ratio to the thickness of their penetration of laser. You can know more about the spot welding system via searching over the internet.

Image source: Google

The laser can be pulsed, with output diverse with points at a time, for example, in an alternating on and off the program. Constant mode, which can be a continuous steady stream, is another choice. In a heartbeat vs. continuous testimonials, it's welder's taste and is determined by the job.

Different from MIG and TIG software, laser welding is readily adapted to robot gear. Laser hybrids can unite laser and arc supplies using a method called gas metal arc welding. The kinds of distribution regulators vary with this program. The hybrid provides better position flexibility throughout the procedure once the molten metal provides as well as the rate of the laser mix for excellent efficacy.

Share this post: on Facebook on Google+