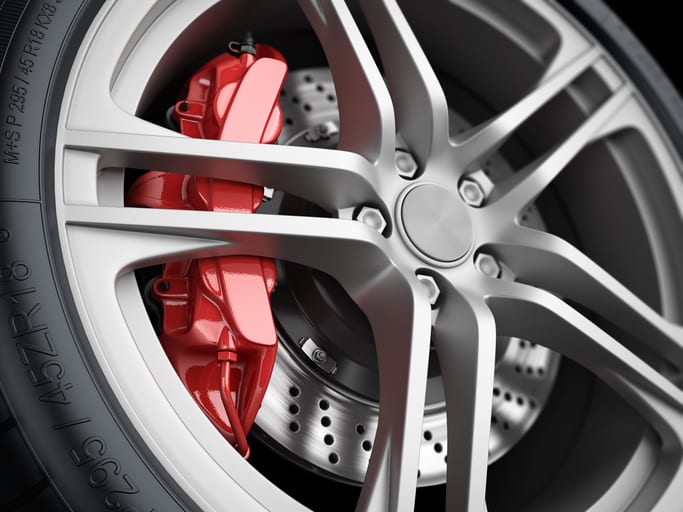

Powder coating is a dry finishing process that involves applying a thin layer of colored powder to a surface. The powder is typically made of finely ground particles of pigment and resin, which are electrostatically charged and then sprayed onto the object. The object is then heated, causing the powder to melt and bond to the surface, creating a durable and attractive finish.

1. Durability and Resistance

One of the main benefits of powder coating is its exceptional durability and resistance to wear, corrosion, and fading. Unlike traditional liquid paint, which can chip, scratch, and peel easily, powder coating forms a hard and protective surface. If you are looking for powder coating services in Westlake Village, then it is recommended to contact https://www.thediamondautosalon.com/powder-coating.

Image source google

2. Wide Range of Colors and Finishes

Powder coating offers an extensive range of colors, textures, and finishes. Whether you prefer a glossy, matte, or metallic look, there is a powder coating option to suit your preferences. This versatility allows you to create customized and unique finishes for your products, enhancing their aesthetic appeal and setting them apart from the competition.

3. Environmental Friendliness

Unlike traditional liquid paint, which contains harmful solvents and volatile organic compounds (VOCs), powder coating is an environmentally friendly option. The powder used in the process is free of VOCs and does not emit any hazardous substances during application or curing.

With its wide range of colors and finishes, resistance to wear and corrosion, and minimal environmental impact, powder coating has become the preferred choice for many industries and individuals in Westlake Village and beyond.